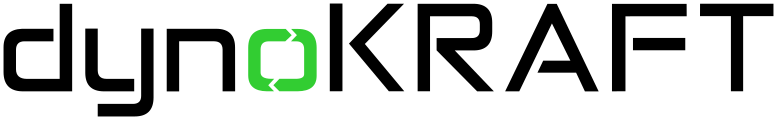

High-end motorcycle and ATV dynamometer

Versatile test system covering largest vehicle range.

Features highlight

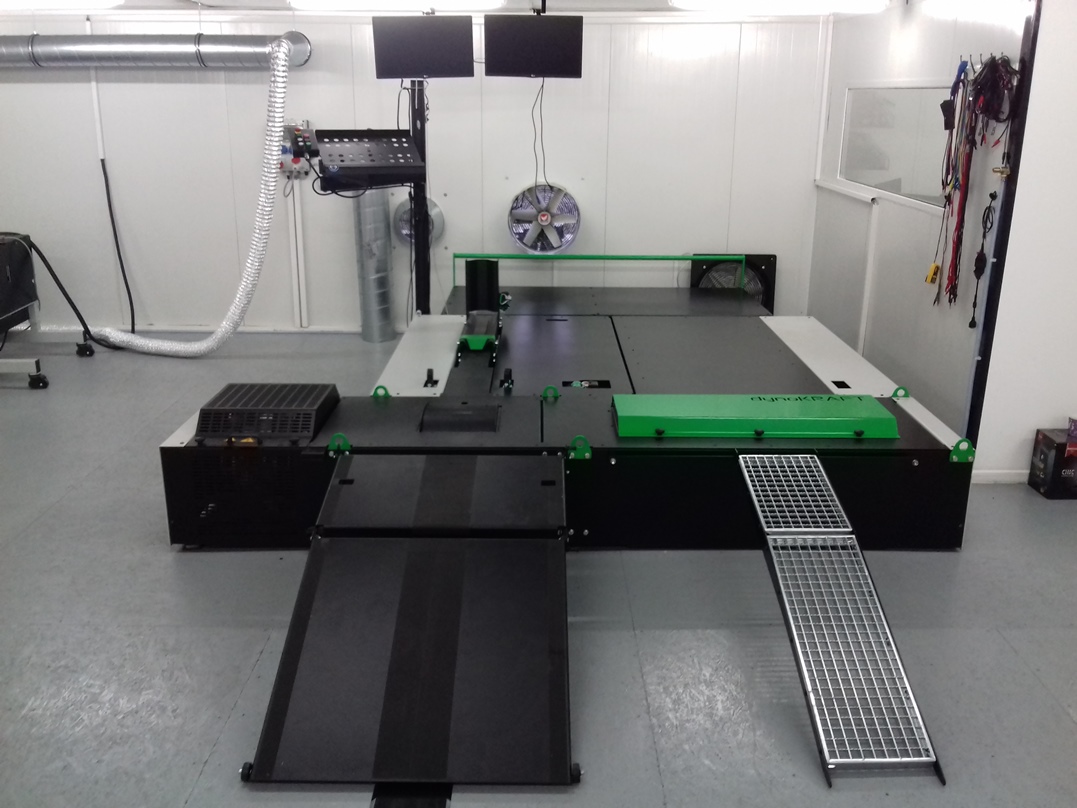

- 440mm [17,3″] roller

- 300km/h [186mph]

- 1000HP wheel power

- front extension bridge

NOTE: Our dynamometers are constantly being developed, therefore we reserve the right to change the appearance and equipment or technical details of our devices, provided this is reasonable for the customer or the deviations are only insignificant. Shape and color deviations are expressly permitted.

Single dynamometer to test motorcycles and ATV’s.

The dynoKRAFT xM200-evo motorcycle and ATV chassis dynamometer offer exceptional high measurement precision together with best-in-class DAQ system and Software for comprehensive data analysis.

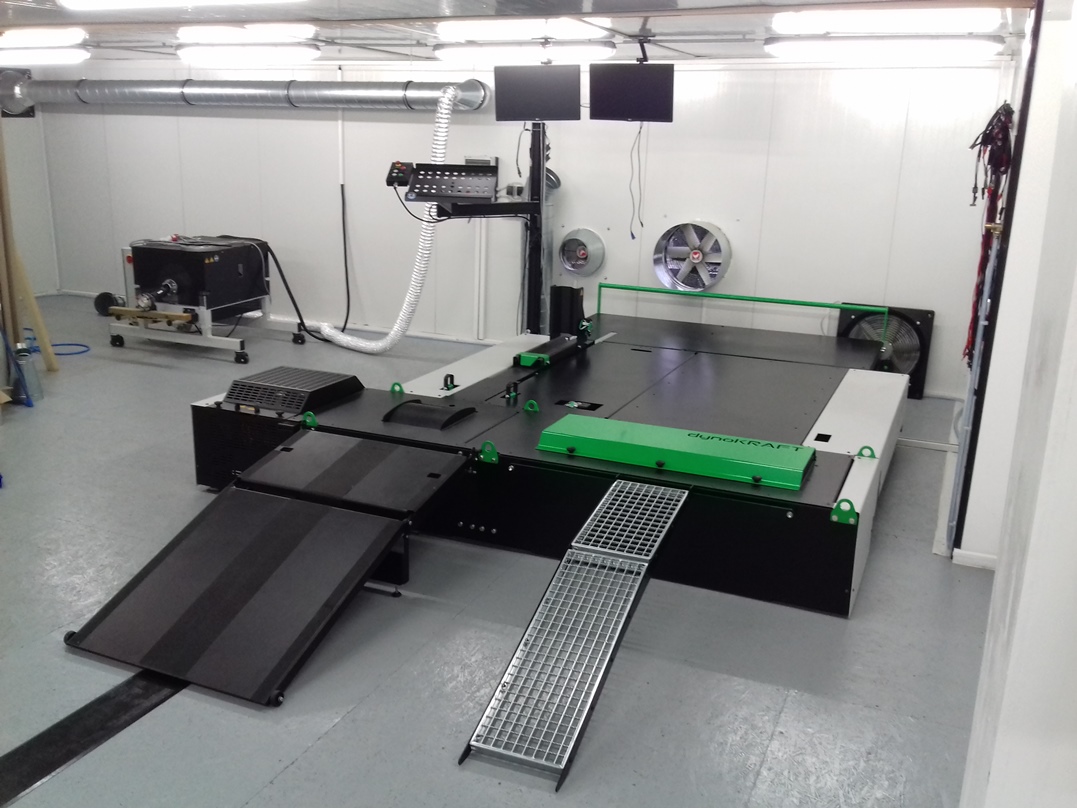

It’s available in both floor-top and pit installation.

With 3140mm length (rear axis to front wheels) and 1925mm track width you can easily test even the largest ATV’s available on the market – even the mighty Polaris RZR XP 4 TURBO EPS or the MAVERICK MAX X rs TURBO will fit on this dyno!

With 2000Nm eddy current brake the xM200-evo is the only chassis dynamometer in the world to offer the ability to test up to 1000HP (at rear wheel).

The roller diameter of 440mm reduce tire wear drastically and help keeping the tire temperature under control during long test sessions.

Accuracy and Precision

- data acquisition error: < 0,5%

- timing accuracy: 10ns

- DAQ input sampling rate: 50Hz

Test parameters

- max speed: 300km/h (186 MPH)

- max wheel torque: 2000Nm

- max wheel power: approx. 1000HP

Data acquisition

- built-in rear tire temp. sensor

- Built-in eddy current brake temperature sensor

- hall effect sensor: drum RPM pickup

- power correction factor per: SAE, DIN, ISO, JIS, EG or none

- available test modes:

– inertia,

– constant engine RPM,

– sweep test (controlled acceleration),

– fully automatic Sequenced/Programmed Test,

– engine RPM steps,

– road loads simulator - Closed-loop eddy current brake PID Controller with torque monitoring

- speed dependent fan control

- multiple input/output channels

- Software relay control (allows remote activation of fans etc.)

- free Software

- free life-time Firmware updates

- engine RPM pickup – inductive and capacitive

- High Speed Ethernet connection

- Remote control of dynamometer and vehicle systems from PC software (throttle actuator, clutch actuator, gear shift, blowers etc.)

- built in CAN-BUS port

- automatic environmental data acquisition

- factory calibrated for highest precision

Mechanical features

- low inertia single roller

- deep-knurled roller surface

- integrated foot-peg strapping system

- anti-slip working surface

- compact design

- fail-safe emergency brake with roller lock

- minimum maintenance

Electric features

- high-torque retarder

- precision load cell

Dimensions

- length: 3595mm *

- width: 3140mm

- height: 440mm

- total height (incl. display post): 1980mm

- roller diameter: 440mm

- roller width: 300mm / 1100mm

- wheelbase min: 1180mm

- wheelbase max: 2280mm / 3000mm **

- track min: 600mm ***

- track max: 1925mm

(*) without loading ramp

(**) motorcycles / ATV’s

(***) smallest width on the inside of the tires

Workshop requirements

- Electric power: 380/400V 50Hz 20A 3-phase*

- Compressed air: 6-8 bar

- Computer: PC with Windows XP, Vista, 7, 8, 10 operating system

*Other electrical systems available on request at no extra charge.

Input specifications

- Engine RPM input (capacitive and inductive clamp included)

- 8x Analog input (0-5V)

- 8x Thermocouple 0-1000 deg. Celcius (Type-K)

- 1x Pulse Counter Input (Ex. detonation counter)

- 1x CANBUS

- 1x OBDII diagnostic interface (optional accessory)

Additional inputs available with CANBUS expansion modules.

(see Accessories tab)

Weather station

- Pressure: 300 to 1100 @ +/-1 [mbar]

- Humidity: +/-3,5% [RH]

- Temperature: -40 to +85 @ +/-1 [°C]

Output specifications

- 8x Digital Outputs (12V relays)

- 1x Air Speed Output (PWM or Analog 0-5V)

- 1x Servo output (PWM, Analog 0-5V or RC-pulse)

Scope of delivery

- dynoKRAFT xM200-evo dynamometer

- loading ramps for motorcycle and ATV (floor-top installation only)

- control panel post with dual monitor holder and keyboard table (floor-top installation only), or PC-Trolley with monitor holder (pit installation)

- weather station with cable

- SP6 Controller with cable

- capacitive and inductive engine RPM pickup

- calibration tool and weight

- free SportDyno software

- free easyMAP software

- installation manual (.pdf file)

- software manual (.pdf file)

- 5 years warranty

- free product support