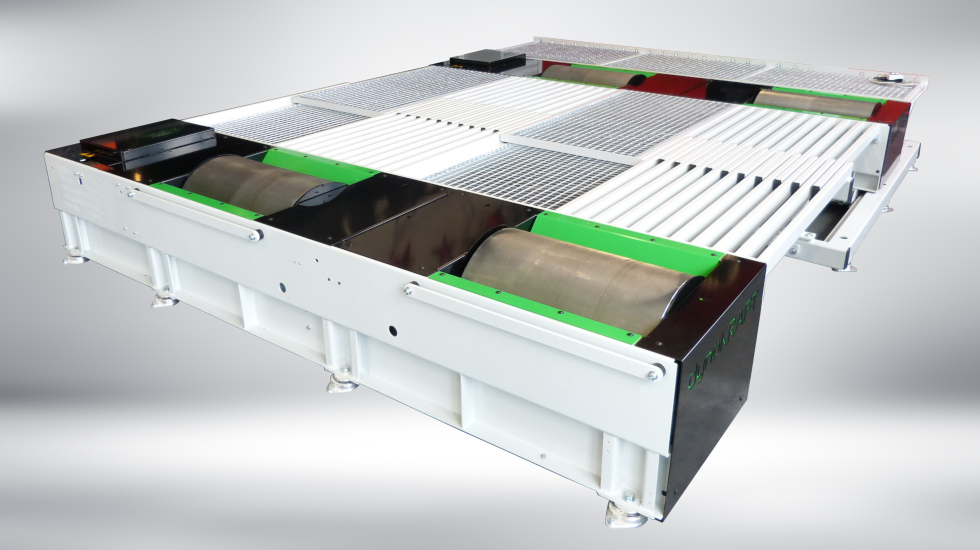

Single roller 4WD dynamometer

Affordable all-wheel-drive dyno with permanent mechanical axis link

Features highlight

- 515mm [20,3″] rollers

- 300km/h [186mph]

- 2x 1000HP wheel power

- mechanical axis synchronisation

NOTE: Our dynamometers are constantly being developed, therefore we reserve the right to change the appearance and equipment or technical details of our devices, provided this is reasonable for the customer or the deviations are only insignificant. Shape and color deviations are expressly permitted.

The all-new A330-Series ist replacing the existing A380- and A200-Series.

Please visit: A330-4WD-ML for details.

The dynoKRAFT A200-4WD-ML automotive chassis dynamometer combines affordable price and precise workmanship with best-in-class DAQ system and Software for comprehensive data analysis.

The dynoKRAFT A200-4WD-ML features unique synchronization system.

It combines both mechanic and electronic axis link thus enabling extreme level of synchronization accuracy and dynamics.

Standard installation type is floor-top. Pit installation available on request.

Roller width of 2170mm allow to test even wide-body race cars without problems.

With two 2000Nm eddy current brake the A200-4WD automotive chassis dynamometer allows to test up to 2000HP (1000HP per axis).

The roller diameter of 515mm reduces tire wear drastically and help keeping the tire temperature under control during long test sessions.

The dynoKRAFT A200-4WD-ML can be freely configured with extension modules (additional inputs, OBD Interface etc…) to match customer needs thanks to our upgradable design concept.

dynoKRAFT A200-4WD-ML | |

Peak wheel torque | 2x 2000 Nm (1,475 ft lbf) |

Peak absorbed wheel power | 2x 745 kW (1000 HP) |

Peak dynamic wheel power | 2x ~930 kW (~1250 HP) |

Max. tractive force | 2x 7767 N |

Power / torque measurement accuracy | 0,5 % |

Max. vehicle driving speed constant / periodic | 285 km/h (177 MPH) / 300 km/h (186 MPH) |

Max. vehicle acceleration rate | 6 m/s² (19,7 ft/s²) |

Max. axle load | 3000 kg (6613 lbs) |

Track width (inside - outside) | 850mm - 2170mm (33,5" - 85,5") |

Wheelbase (min - max) | 2100mm - 3300mm (82,6" - 129,9") |

Roller diameter | 515mm (20,3") |

Rotational inertia equivalent vehicle mass | 430kg (948 lbs) |

Dimensions L x W x H (outside) | 4861 x 3345 x 618mm (191,4 x 131,7 x 24,3") |

Weight (total) | 3450kg (7606 lbs) |

Rotational mass weight | 865kg (1907 lbs) |

Rollers balancing class | G2,5 or better |

Mechanical link system type | HD bevel gearboxes, permanent |

Warranty and Support | 1 Year |

Scope of delivery |

|

ADAQ controller - Technical specifications | |

ADAQbase (base dynamometer control module) | INPUTS: 2x RPM (hall-sensor or digital 5V) 2x Load Cell with built-in amplifier 3x Analog 0-5V DC, configurable 1x Thermocouple Type-K 1x Built-in weather station (ambient temperature, humidity, pressure) OUTPUTS: 2x Brake controll, configurable as PWM, RC-Pulse, Analog, Servo PC CONNECTIVITY: 1x USB-C |

ADAQexiom | INPUTS: |

ADAQpower | FEATURES: |

ADAQremote - XenceLabs Quick Keys Remote | FEATURES: -8 Keys / 4 Sets with assignable software functions- built- in battery - built-in battery charging circuit - USB-C connection - USB-Receiver included |

ADAQsoftware | MAIN FEATURES: |

ADAQexiom plugin | BASE FEATURES: |